Home >

Show information >

Nanchang Mineral Systems Shines at the 2024 China International Mining Conference, Leading Industry Lifecycle Services with Intelligent Operation and Maintenance Platform

Home >

Show information >

Nanchang Mineral Systems Shines at the 2024 China International Mining Conference, Leading Industry Lifecycle Services with Intelligent Operation and Maintenance Platform

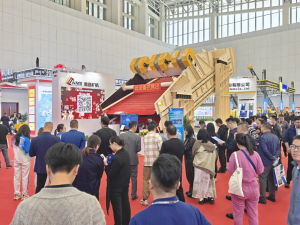

From October 15 to 18, the 2024 (26th) China International Mining Conference successfully wrapped up at the Tianjin Meijiang Convention and Exhibition Center. As a leader in the mining equipment field, Nanchang Mineral Systems showcased its innovative product—the large 2MLS43100-F box-type vibrating screen and the intelligent operation and maintenance platform, receiving widespread acclaim from industry experts and attendees.

Intelligent Operation and Maintenance Platform: Leading Digital Transformation

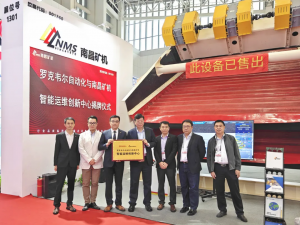

On the morning of the 15th, Nanchang Mineral Systems and Rockwell jointly held the unveiling ceremony for the Intelligent Operation and Maintenance Innovation Center, along with the “Intelligent Operation for a Win-Win Future” project demonstration. Yang Zhenghai, General Manager of the Mining Division at Nanchang Mineral Systems, stated in his speech that in recent years, the company has actively embraced change, fully promoting its transformation toward digitization, intelligence, and sustainability. The establishment of “Intelligent Operation and Maintenance” has become one of the core pillars of the “Service NMS” strategy, regarded as a key driving force within the company’s three core business segments—aftermarket services. Since the partnership between Nanchang Mineral Systems and Rockwell began in May 2021, both parties have worked closely together to successfully build the intelligent operation and maintenance platform. This platform enables Nanchang Mineral Systems to provide comprehensive intelligent crushing and screening plant solutions for its clients, helping them achieve refined management, reduce costs, improve quality, and enhance efficiency, thereby strengthening their market competitiveness.

General Manager Yang Zhenghai also mentioned that back in 2021, at the 23rd China International Mining Conference, the company announced its phased achievements in intelligent transformation—the Intelligent Operation and Maintenance Platform. Now, three years later, this platform has achieved significant advancements. To date, Nanchang Mineral Systems has successfully implemented multiple intelligent operation and maintenance projects, receiving high praise from clients. With the unveiling of the Intelligent Operation and Maintenance Innovation Center co-built with Rockwell, we eagerly anticipate a new chapter in Nanchang Mineral Systems’ journey toward intelligent transformation, creating more value for clients. This will enable the intelligent operation and maintenance business to enter a new development phase, providing full lifecycle services to more clients and promoting high-quality development in the industry.

Subsequently, Li Dong, the Director of Rockwell Automation’s Intelligent Manufacturing Research Institute, also delivered a speech. He began by expressing gratitude for Nanchang Mineral Systems’ warm invitation and praised the company’s outstanding achievements in the mining equipment sector. Director Li stated that as an important partner of Nanchang Mineral Systems, Rockwell provides key technological support, including the industrial Internet of Things ThingWorx system, an integrated vibration condition monitoring system for predictive maintenance, 3D SCADA, and basic automation control systems. The teams from both sides have worked together to establish the Intelligent Operation and Maintenance Innovation Center, leveraging their precise understanding of customer pain points, strong technical expertise, and a commitment to excellence in project delivery.

Director Li also mentioned that in the future, Rockwell will continue to deepen its collaboration with Nanchang Mineral Systems in digital areas such as Intelligent Power IPP, Process Optimization APC, and Equipment Asset Management EAM. This ongoing partnership will support Nanchang Mineral Systems in providing high-end intelligent equipment services and full lifecycle services to mining users, injecting stronger momentum into the high-quality development of the mining machinery sector.

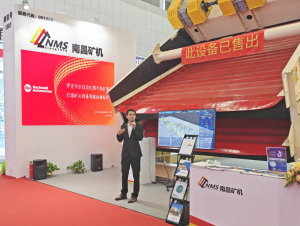

Rockwell’s Mining Industry Business Development Manager, Wu Yang, and Nanchang Mineral Systems’ Intelligent Operation and Maintenance Center Director, Meng Zhi, respectively provided introductions regarding the intelligent operation and maintenance project.

Innovative Products Showcase Technical Strength

At the event, the 2MLS43100-F box-type vibrating screen from Nanchang Mineral Systems was undoubtedly one of the highlights. This screen, designed for grading particle sizes from 0.25 to 30 mm, features a screening area of 43㎡ per layer and can be widely applied in industries such as metallurgy, coal, and mining for grading fine particles and sticky materials. It is suitable for mud removal before crushing and closed-circuit screening after high-pressure roller processes.

The unique layered motion characteristics of the box-type vibrating screen allow the vibration intensity of the screen frame to reach 30 to 50g when the vibration intensity is set at 3 to 4g, effectively promoting material dispersion and screening while avoiding material agglomeration. Additionally, the tension and relaxation motion of the screen mesh causes some deformation of the screening holes, providing a self-cleaning effect for materials sticking to the mesh and effectively preventing blockage, ensuring optimal screening efficiency and results.

Moreover, the 2MLS43100-F box-type vibrating screen boasts several advantages, including a large excitation force from the box vibrator, high throw acceleration, stable performance with standard SKF/FAG imported bearings, high structural strength in the screen frame design, good elasticity and high open area of polyurethane screening mesh, and low operating noise with composite springs. These features effectively address the challenges of screening sticky materials, providing more efficient and reliable screening solutions for the mining industry.

In addition to the showcase of the intelligent operation and maintenance platform and the debut of the 2MLS43100-F box-type vibrating screen, the MDI high-performance polyurethane screen brought by Nanchang Mineral Systems’ subsidiary, NMS New Technology Material Co., Ltd., was also well received by many attendees. Furthermore, Nanchang Mineral Systems organized a lucky draw and other activities at the event, attracting active participation and attention from numerous guests.