2024.09.20

2024.09.20

As August ends, Guangming Xu, aged 61, has officially retired after being re-employed for a year by NMS Group. A banner reading “Hard work bears fruit; grateful to contribute, joy in retirement,” succinctly captures the essence of his 41-year career.

Devotion Across Roles

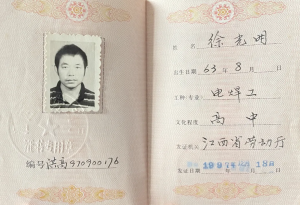

Born in 1963 in the Qingyunpu District of Nanchang, with ancestral roots in Shandong, Xu initially aspired to be a professional athlete. Unable to meet the requirements for a tier-three athlete, he joined the Nanchang Mining Machinery Factory (precursor to NMS) as a welder in September 1983. This marked the beginning of his 41-year tenure with NMS, during which he witnessed and helped drive the transformation of a small machinery factory into a renowned national mining machinery manufacturing enterprise.

According to Xu’s recollections, the factory primarily produced bucket elevators, screw conveyors, small circular vibrating screens, and self-centering vibrating screens at that time, which were sold to coal mines, mining sites, and building materials factories in Pingxiang and Fengcheng. In the late 1980s to early 1990s, the factory began manufacturing pelletizers and ball mills. After the restructuring in 2003, the production shifted to large vibrating screens and vertical shaft crushers, gradually expanding the variety of products.

At that time, there were about 50 workers in the sheet metal workshop, and they used drooping characteristic welding machines. As the current increased, the voltage automatically decreased, ensuring smooth welding. Now, the sheet metal workshop has around 30 workers, but welding has long switched to flat characteristic welding equipment, where the voltage remains within a fixed range, ensuring higher weld strength and production efficiency, thus reducing the need for as many workers in welding positions. The working environment is also much improved, with every workstation now equipped with cooling fans and fume extraction systems, whereas in the past, there weren’t even electric fans.

After the company’s restructuring, due to work requirements, Xu transitioned to process work under the guidance of external experts, drafting sheet metal and welding process documents. With his solid technical knowledge, he helped solve welding issues that arose during operations and guided standardized practices in the workshop. In 2010, Xu moved to quality control, where he began working as a quality inspector.

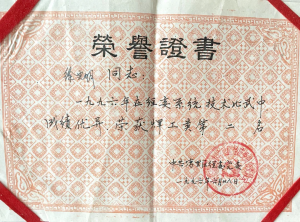

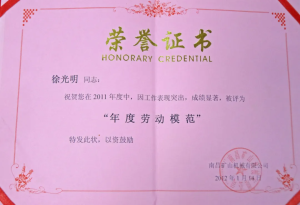

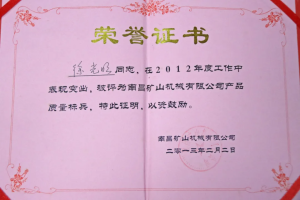

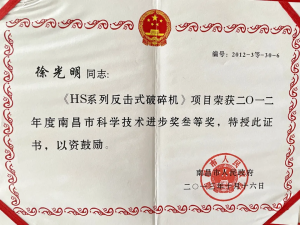

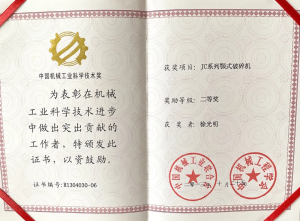

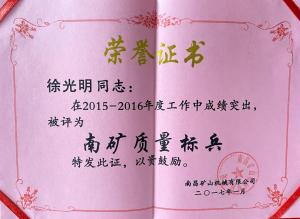

Though Xu changed roles several times during his career, he remained dedicated to every position he held, always striving to excel. In 1996, Xu won second place in the welder category during a technical competition within the Economic Commission system. In 2012, he contributed to the HS series impact crusher project, which won third place in the Nanchang Science and Technology Progress Award, while the JC series jaw crusher project won second place in the 2013 China Machinery Industry Science and Technology Award. Xu was also recognized as a model worker in 2011, and he won several quality awards from 2011 to 2016, including being named NMS Quality Champion multiple times. These honors are a testament to Xu’s unwavering dedication and hard work.

Paying Attention to the Details

“Quality inspection is about spotting issues, preventing losses, and thus creating value,” says Xu, explaining his approach to quality control. When asked about the differences between welding and quality inspection, he noted that welding is physically demanding but requires less thinking, while quality inspection may seem easier but demands constant vigilance. Small defects, if left unnoticed, can lead to significant problems.

Xu recalls a time when the installation of the moving cone body of the first CC800 cone crusher failed three times. After careful inspection, he discovered that the issue was caused by an inadequately heated weld spatter inside the equipment. Though it seemed like a minor flaw, it could have severely impacted the equipment’s installation and performance if left unresolved. Xu emphasizes that the focus has shifted from final product inspection, which was costly and difficult to fix if mistakes were found, to proactive process control and timely feedback. In his words, “You fix it before the salt gets in the pot.”

Xu also mentions that quality and production departments often experience conflicts. At first glance, faster processes seem to increase efficiency and profit, but in reality, prioritizing speed over quality can lead to rework, scrap, or even customer returns, which can damage the company’s reputation. Xu’s strategy to resolve disagreements is to communicate well and use technical knowledge to persuade production staff to follow correct procedures. He acknowledges that the waiting time for rework creates pressure on quality inspectors but points out that workers’ awareness of quality has greatly improved over the years, reducing conflicts. Now, everyone understands that maintaining quality is key to job security, and while differing opinions still arise, they are resolved through constructive discussions.

Guangming Xu And Linsheng Fang(Left)

“There’s no question—he’s always been diligent and dedicated,” says Linsheng Fang, who works in the oil station assembly section of the assembly workshop. Fang speaks with admiration for Xu, especially as Xu continued to oversee the oil station assembly inspections right up until his retirement. His colleagues chose to express their respect for Xu not with emotional farewells but with lighthearted jokes, reflecting the deep bond and mutual recognition in the workshop.

Faith and Original Intent

Xu says that his favorite thing is going to work. At first, this statement might seem surprising—how could someone enjoy going to work so much? But on reflection, it might just be his truest sentiment. From graduating high school to retiring, Xu dedicated his entire career to NMS Group, spending most of his life at work. Together with the company, he weathered the storms, grew, and found personal fulfillment. His work provided for his family, raising two daughters, and now, with grandchildren, he remains deeply connected to his career.

Xu shares two life lessons: First, have faith in yourself. If you believe in yourself, you can solve problems. Second, stay true to your original intent. Those who are easily content will always find happiness. “For example, my goal in working was simply to make sure my family had enough to eat. As long as I achieved that, I was very satisfied. Constantly wanting more will only lead to suffering.”

As for his retirement plans, Xu says he will help take care of his grandchildren before buying a car to go traveling. However, for someone like Xu, who loves his work, adapting to retirement may take a little time.