2024.12.04

2024.12.04

Kun Li, 56, is the Chief Engineer of the Product Development Center at the NMS Technology Equipment Research Institute. Throughout his career, the word “focus” perfectly encapsulates his character.

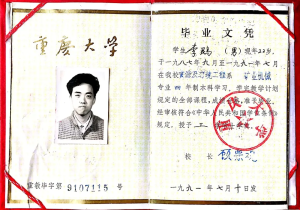

Since graduating from Chongqing University with a degree in Mining Machinery in 1991, Li has been quietly working at Nanchang Mineral Systems (NMS) for 33 years.

Kun Li Graduated from Chongqing University in Mining Machinery

Recalling the year he joined NMS, Li recalls that the company’s Wanli factory was still made up of old buildings, with only sheet metal and metalworking workshops, and the casting workshop was still located at the Ziqing Mountain plant. Assembly was even carried out outdoors. Although there were over 400 employees, the dormitories were old red-brick buildings, and the canteen had no dining tables. Employees had to either squat and eat outside or take their meals back to the dormitory. Li laughed, saying that at the time, the company’s environment was even worse than the one at our university.

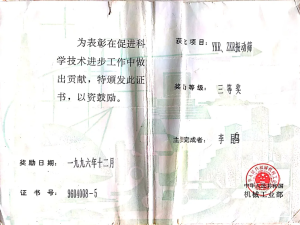

However, Li was not deterred by the modest conditions. He started as an assistant engineer in the Technical Department. At that time, NMS had already developed the YKR and ZKR models of vibrating screens, mainly used for coal washing and screening. Li’s main job was to work on making these models more standardized. Li continued working on the development of vibrating screens until December 2002, focusing his energy on product upgrades and innovations with dedication and persistence.

Kun Li Participated in the Development of YKR, ZKR Vibrating Screens, Winning the Third Prize of the National Science and Technology Progress Award

Under Li’s leadership, a wide variety of vibrating screens were developed and successfully used in different industry sectors, receiving praise from all corners. In 1993, NMS captured nearly 90% of the screening equipment market share for the Three Gorges Project, and with the excellent performance of these screens, NMS gradually expanded its business into the metal mining and engineering construction fields. Over time, NMS’s vibrating screens became a well-known domestic brand, laying a solid foundation for the company’s stable development.

Application of Vibrating Screens in a Project Site

In 2003, NMS underwent a historic transformation. With the reform of its corporate structure, the company realized that to remain competitive in the market, it needed to continue developing new products. Focusing on just vibrating screens was no longer enough. New directions had to be explored.

In 2005, NMS established Shanghai Kaicai Industrial Co., Ltd., to actively explore the overseas market. Under the leadership of the company, Kun Li and his colleagues moved to Shanghai, dedicating themselves to product research and development. Shanghai, known as a hub of innovation, hosted numerous industry exhibitions, bringing cutting-edge information and facilitating access to advanced knowledge and technologies. This allowed the research team to focus on innovation and development away from the busy workshops.

Kun Li, drawing on international technological insights and combining his extensive experience in mechanical design, made a series of improvements and optimizations to the jaw crusher. After much effort, NMS’s first jaw crusher, the JC1100, was developed.

However, the path of innovation is never smooth. When the first JC1100 jaw crusher was put into use at an aggregate project site in Shandong, it faced significant challenges such as abnormal vibration and frequent motor casing damage. Kun Li and his team quickly responded by checking the ground level, adjusting the equipment’s balance, and repositioning it. They successfully solved the problem of excessive vibration.

Thanks to the lessons learned from this first installation, subsequent JC1100 crushers were successfully deployed with adjusted vibration levels, ensuring smooth operation. These improvements not only enhanced the reliability and durability of the equipment but also laid the groundwork for the company to establish a comprehensive set of standards for jaw crushers.

Kun Li on a Business Trip in Shandong

Subsequently, based on market demands, Kun Li participated in the development of multiple models of jaw crushers, including the JC1200, JC1300, JC1150, JC0850, JC1000, JC1400, JC1200M, JC1600, JC2000M, and JC2200. These crushers were gradually standardized and adapted for larger sizes. As of now, over 500 jaw crushers developed with Li’s involvement have been sold.

While developing various models, Kun Li has also focused on improving product performance. The early models, like the JC1100 jaw crusher, used manual mechanical adjustments for the discharge opening. By the time the JC1200 was introduced, hydraulic adjustments were implemented for greater ease and efficiency. Additionally, the use of ABB soft starters reduced the impact on equipment during startup, and sensors were added to monitor bearing temperatures, ensuring their safety.

Kun Li shared that with the continuous development and growth of NMS, the workshop’s equipment processing capabilities have also undergone significant improvements. In the past, heat treatment work had to be outsourced, but after purchasing a trolley furnace, large structural and welded components can now be fully annealed in-house, ensuring more stable product quality. Previously, using small boring machines to process large jaw crusher frames was a challenging task. However, with the introduction of large boring machines, processing efficiency has rapidly increased. Additionally, welding methods have evolved from traditional manual welding to more efficient techniques like submerged arc welding and gas-shielded welding, which have sped up the welding process. As the company expanded, communication and collaboration with external partners became more frequent, and NMS established close cooperation with several universities and research institutes. This collaboration brought rich external resources, significantly expanding the channels for gathering data and providing convenient conditions for product innovation and development.

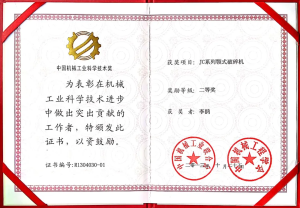

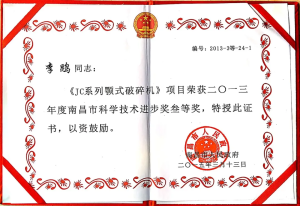

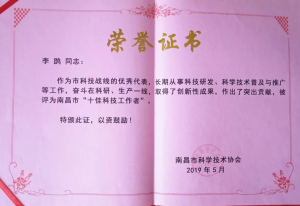

Kun Li, as a key contributor to the development of the JC series jaw crushers, was awarded the second prize of the China Machinery Industry Science and Technology Award and the third prize of the Nanchang City Science and Technology Progress Award.

Kun Li was also named one of the “Top Ten Technology Workers” in Nanchang.

As the product range expanded and more application projects emerged, the variety of working conditions increased, which brought about new challenges. In facing these issues with mass production, Kun Li has always remained calm and patient. He understands that perfecting a product is a continuous process of problem-solving. Therefore, he leads his team to constantly improve and refine the products, ensuring that each piece of equipment runs stably and meets customer needs. When the first JC1600 jaw crusher was used at a project site in Henan, the large equipment required a high-pressure motor. However, the large motor caused issues with the motor frame and junction box not being resistant to vibrations, which led to frequent damage. Similar feedback was received from other JC1600 jaw crushers sold at the same time. After an on-site inspection, Kun Li strengthened the motor frame and later solved the issue by altering the motor installation method and adjusting the equipment structure.

Kun Li at the project site

“I believe that when developing a product, you must have the courage to make it happen from the very beginning. You will never know if it will succeed unless you try. After the product is made, you must keep improving it, which will make it better and better. Also, you must be good at learning and absorbing advanced domestic and international technologies and carry out research based on the knowledge of those who came before us,” said Kun Li.

Kun Li (second from the left) with his colleagues

Today, Kun Li is not only a key technical backbone of NMS but also a role model and mentor for younger engineers. He humbly says that there is still much he needs to learn and improve. At the same time, he looks forward to leading a group of young people into new areas of equipment development, hoping to soon develop more innovative products that will help extend the product line of the company.

“I will strive to do my job well and guide the new employees,” Kun Li said, making this a commitment to himself. In the days to come, he will continue to write his own technical legend with a spirit of “dedication” .