2020.11.18

2020.11.18

To get the most out of your cone crusher it is important to configure it correctly. Often this is viewed as some sort of dark art but with some basic guidance it is not that hard to do. This paper is intended to introduce the topic of crushing chamber selection and how to keep crushing performance high during the lifetime of the crushing chamber. The paper will also give guidance on what can be done to both detect and address some common problems. It is good to have some basic understanding so this paper starts off with some theory and then connects the theory into some practical applications.

In order to understand why certain things happens in the cone crusher it is good to have some insights in the actual crushing process. In this paper we will start up with a little bit of theory on what happens with the rocks as they pass through the crushing chamber.

During one revolution of the crusher the rock material will both fall and be crushed. The falling occurs from the moment the mantel starts to move away from the concave and ends when the mantle have closed enough to again grip the material. During the fall phase the material first falls freely and sometimes it also slides against the mantle. Once gripped the downward motion stops and the material is crushed. This process is repeated over and over until the material has reached the bottom of the crushing chamber and falls out. Each of these crushing events is often referred to as a crushing zone, see Figure 1.

Figure 1. The crushing zones. The material is first crushed in the first crushing zone, when the mantle moves away from the concave the material will fall into the second crushing zone and be crushed again. The process repeats itself until the material reach the bottom of the chamber and falls out of the crushing chamber.

Since the cavity formed by the mantel and concave have more or less of a funnel shape the size of the crushing zones will vary. The smaller the zone the less material can fit into it. In all crushers there will be a zone with smallest volume and that is referred to as the choke zone. The volume of the choke zone is what determines the crusher throughput capacity.

The location of the choke zone varies depending on the crushing chamber, in general it is at the very bottom for the coarsest chamber and then gradually moves upwards as the chambers becomes finer.

For the continuation of this paper we will come back to the theory of crushing zones so you might want to refer back to this section while reading the paper.

Often selection of a crushing chamber is regarding a bit of a mystery but in reality, it is not that hard to get the basics right. When starting the selection process there is one factor more important than all others: chamber max feed size. When selecting crushing chamber review the maximum feed size, the chamber should be selected so that the crushing chamber specified feed size is larger than the rock material max size. The chamber max feed size is not to be mistaken for chamber intake opening. So the specified max feed size will have some margins so no tolerance is needed when the chamber is selected. One exception from this might be if the rock material is extremely elongated or flat but those cases are rare.

So why is it important to select a crushing chamber that matches the feed size? There are mainly two reasons for this: Reduction and wear.

In general the crushers ability to crush at a smaller setting gets better and better as the chamber becomes finer. If you look at the capacity table of different crushing chambers for a crusher you will notice that the minimum closed side setting (CSS) is smaller for a fine chamber compared to a coarse chamber. Often you want to be able to run the crusher at a small setting to efficiently crush the rock into the desired size and to do that a small CSS is needed.

Another thing worth noting about crushing chambers is that as they get coarser, they will have a larger capacity. Based on this one might be tempted to abandon the rule of selecting chamber based on feed size. It is easy to think that if you do not need the small CSS why do not select a coarser chamber and thereby increase the crusher capacity. This is totally feasible, but it will come at a price.

As mentioned above the second reason for selecting a crushing chamber based on feed size is wear. If a coarser than needed chamber is selected the material entering the crushing chamber will be significantly smaller than the intake opening. The consequence of this is that there will be no crushing in the upper part of the chamber, instead all crushing will take place further down in the chamber. No crushing in the upper part means no wear. All wear will instead be focused to the lower part of the crushing chamber. Again, if the material abrasiveness is low this might not be a big problem but for most plants the down time and effort to replace crusher wear parts has significant effect on productivity. So, in order to maximize wear part utilization and minimize downtime, it is important to select the chamber with the correct max feed size.

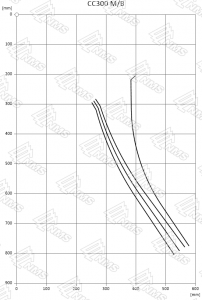

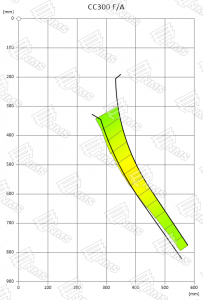

For a given crushing chamber there are often more than one mantle. They are often referred to as A and B mantle. (This is only valid on crushers with several eccentric throws.) The profile of mantle A and mantle B are very similar, but they sit at different position on the head center. The A mantle sits higher than the B mantle. The reason for needing more than one mantle is that the position of mantle changes with both eccentric throw and CSS. It is always advisable to have the mantle position inside the concave, otherwise there will be no wear on the bottom part of the mantle, this will create a poor wear profile which will have a negative effect on the crusher performance. For an illustration of a mantle sitting below the concave see Figure 2.

Figure 2. CC300 with M concave and A mantle. Eccentric throw 44 mm, CSS 15 mm. (The mantle is shown in open, neutral, and closed position)

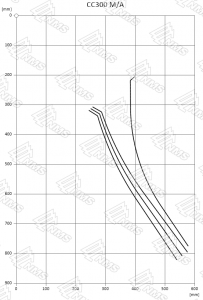

To correct the problem in Figure 2 the mantel should be replaced with a B mantle, see Figure 3.

Figure 3. CC300 with M concave and B mantle. Eccentric throw 44 mm, CSS 15 mm. (The mantle is shown in open, neutral, and closed position)

So, if the crusher has a bigger throw the mantle needs to be position further down so it has room to swing to reach the CSS. To position the mantel further down it needs to sit lower on the head center, otherwise the main shaft cannot be lowered enough. On the other hand, if the crusher has a smaller throw the mantle will need to swing a smaller distance and can be positioned higher. This is illustrated in Figure 4 where the throw has be reduced from biggest (Figure 3). The benefit of using an A mantle when possible is that it will give the crushing chamber a longer wear life.

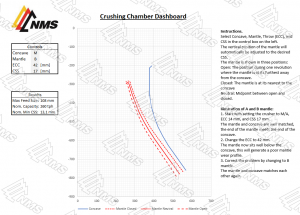

We understand mantle and concave selection might seem to be complicated. So, to give a more hands on experience we have created an Excel dashboard, it can be downloaded from the same place as this paper. Give it a try and we are convinced you will think the A and B mantle selection is easy to understand, see Figure 5

Figure 4. CC300 with M concave and A mantle. Eccentric throw 16 mm, CSS 15 mm. (The mantle is shown in open, neutral, and closed position)

Figure 5. The NMS Crushing Chamber Dashboard. The dashboard runs in MS Excel and is a great tool to understand crushing chamber configuration.

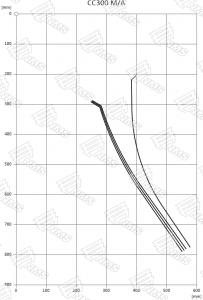

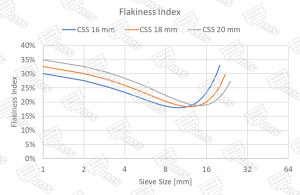

A cone crusher has one parameter that can be controlled on a continuous basis, namely CSS. CSS has a big impact on product gradation, and it is important to keep it under control. Since CSS is affected by wear on the mantle and concave it is important to measure and adjust frequently, in most cases daily. The CSS effect on gradation is as it becomes smaller the gradation gets finer, see Figure 6.

Figure 6. Crusher operated on 16 mm, 18 mm, and 20 mm (from left to right curve).

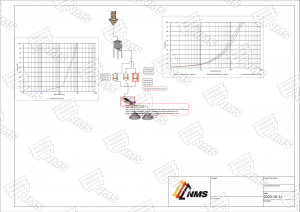

In addition to finer gradation the capacity will also decrease. If you remember that the size of the choke zone determines the capacity. When the mantel and concave is brought closer to each other to make the CSS smaller the size of the crushing zone becomes smaller, see Figure 7.

Figure 7. When the CSS becomes smaller the mantle moves upwards. This will limit the space between the mantle and concave, hence making the crushing zones smaller.

When adjusting the CSS the shape will also be affected. Research has shown that the best product shape is found at the same size as the CSS. Sizes larger and smaller than CSS will have gradually worse shape, see Figure 8.

Figure 8. Illustration of the CSS effect on particle shape.

When optimizing shape there is also a second parameter that should be considered, the reduction ratio. In general, better shape is generated when the reduction ratio is moderate. This could be good to know if the plant is operated in such a way that the crusher feed is altered. One could also improve the shape by increasing the reduction ratio (run at smaller CSS) in the previous crushing stage.

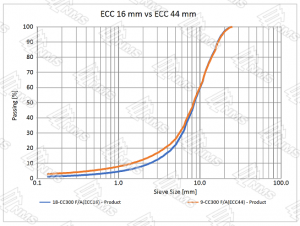

In addition to the CSS the eccentric throw is sometimes mentioned as an option for crusher optimization. In practice it is hard to utilize this on an already installed crusher for optimization of gradation or shape. The main effect eccentric throw has is adjusting the capacity and that is what it should mainly be used for. Eccentric throw will also affect both gradation and shape but the effect is small. To be able to measure the eccentric throws effect on those two parameters several steps of the eccentric bushing must be adjusted. Increasing the eccentric throw will mainly influence the finer part of the gradation curve. Bigger eccentric throw will increase the fines production and improve the particle shape. Shape and fines often go hand in hand, and this is no exception. So, comparing a crusher running on the smallest throw with a crusher running on the biggest throw you can except the crusher with the biggest throw to produce better shaped product and a higher percentage of fines.

Figure 9. Crusher operated with two different eccentric throws, smallest 16 mm and biggest 44 mm.

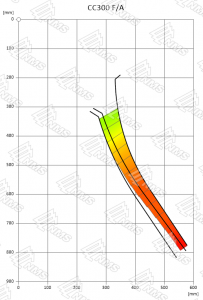

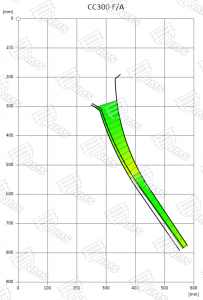

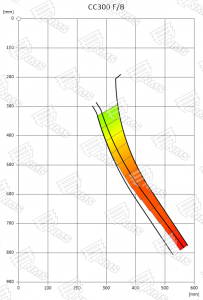

The explanation is that with a small throw the material is crushed more gently in several small steps (many crushing zones), see Figure 10. The big throw will do the whole work in few crushing zones where the crushing pressure is relatively high, see Figure 11. As stated before, the effect is relatively small and the if you have an issue with excessive fines in an existing crusher it seldom make sense to reduce the eccentric throw to reduce the fines production. The capacity will drop to something like 50% before you see a clear effect in the percentage of fines produced.

Figure 10 Crusher operated with 16 mm eccentric throw. The color indicates crushing pressure going from low (green) to medium (yellow). The mantle is shown in both open and closed position.

Figure 11. Crusher operated with 44 mm eccentric throw. The color indicates crushing pressure going from low (green) to high (red). The mantle is shown in both open and closed position.

So to make the process optimization efficient, use eccentric throw to adjust the capacity and the CSS to adjust the gradation. Trying to fine-tune gradation using eccentric throw is not to recommend, the effect of changing the eccentric bushing a step or two will not make a notable difference in gradation while you change the capacity with 10-20%.

Apart from keeping a close eye on the CSS during operation one should also make sure that the crusher is operated choke fed. Choke fed means that enough material is present in the crusher hopper to allow for material to fill the chamber. In terms of recommendations one should aim to cover the spider bearing house in fine and medium applications. On coarse applications it might sometimes be advisable to keep the level lower. In coarse applications a high level might cause bridging or hinder the material flow due to rocks interlocking.

Secondly it is also important to have an evenly distributed feed in the crushing chamber. Rocks of equal distribution should be present around the inlet of the crushing chamber. Short term, uneven distribution can be tolerated but if this is the statues quo it will cause problems. As mentioned before it is important to have rock of proper size fed to the crushing chamber. What happens with uneven distributions is that the material constantly will be too fine in parts of the chamber. The wear will therefore vary around the chamber, more in some parts less in others. This will make the concave loose its roundness and the CSS will vary around the chamber. In other words you are starting to loose control of the most important factor for productivity. This could eventually lead to so poor crusher performance that the crushing chamber must be replaced prematurely. This will cause both downtime and poor utilization of the mantle and concave.

Sometimes it is obvious that the crusher feed is misaligned or unevenly distributed. In those cases, something needs to be done. There are cases where the problem is more difficult to observe or quantify. One good way to evaluate is the thickness of the worn-out concave. Measure the thickness of the bottom part of the concave. The difference between thickest and thinnest must be significantly smaller than the crusher CSS. Hence a couple of millimeters out of roundness on a coarse chamber is not a big issue but on a fine chamber running on a small CSS a couple of millimeters in deviation on part of the chamber will affect the productivity. Especially if the crusher is running on minimum CSS where maximum reduction is needed.

In this paper the selection of crushing chamber was demonstrated. As mentioned, it is important to get this right because it has a significant effect on the crusher performance and plant productivity. The paper also stressed the importance of keeping an eye on the crusher during operation. It is important to know what to look for and to understand when problems need to be corrected and when it makes more sense to focus on something else. What we now would recommend you to do is to review your cone crushers. Do they have the correct crushing chambers? Are they fed properly? Do the worn-out wear parts look evenly worn? You should not be surprised to find issues that you can correct and thereby improve productivity.