Home >

Corporate News >

Unstoppable! NMS Joined in Fairs and Looked Forward to Future with Enterprises in Industry

Home >

Corporate News >

Unstoppable! NMS Joined in Fairs and Looked Forward to Future with Enterprises in Industry

2020.12.16

2020.12.16

This December is a busy month full of exhibitions and meetings, Nanchang Mineral Systems Co., Ltd. (hereinafter referred to as “NMS”) showed up in several important exhibitions and meetings around the country, demonstrated its overall business capabilities to domestic and overseas customers and promote communication and cooperation with them.

Ⅰ. 2020 China Concrete Exhibition

Dec. 4 to 6

Nanjing City, Jiangsu Province, China

From Dec. 4 to 6, 2020 China Concrete Exhibition was held in Nanjing International Expo Center. The exhibition was hosted by China Concrete and Cement-based Products Association, and the 2020 China Concrete and Cement-based Products Industry Conference was held at the same time.

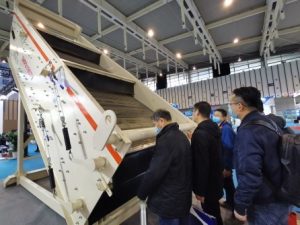

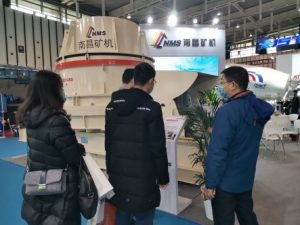

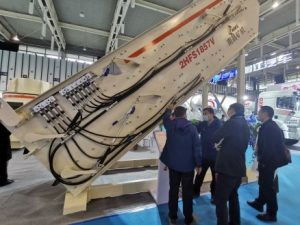

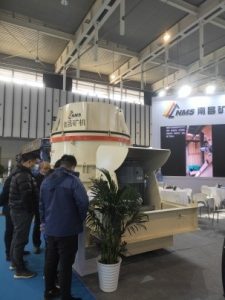

During the exhibition, NMS took its VSD dual chamber VS impact crusher and HFS/V hydraulic high-frequency screen, appearing in 2020 China Concrete Exhibition and fully demonstrating its scientific research capability and innovative spirit.

VSD1450 dual chamber VS impact crusher adopts the new structure with dual rotor, dual crushing chamber and single spindle. It is suitable for making sand for brittle non-metal materials with medium hardness and compressive strength below 140MPa. The equipment has high production efficiency, high sand forming rate, low powder content, energy saving and other advantages, especially it’s a good solution to small material crushing problem. The equipment shows the advanced technological achievements of new products, technologies and materials.

2HFS1857V hydraulic high frequency screen adopts original imported hydraulic vibration pump for drive, frequency can be adjusted by hydraulic flow rate; its advanced screening principle, the rough material is bounced higher and the fine material contacts the screen surface more frequently; high frequency screening is realized by beating screen surface with vibration beam. The vibration intensity is large and the structure of vibration beam is simple and reliable; quick and convenient mesh tension mechanism for easy onsite replacement; advanced hydraulic control system, its main components are imported parts. Each vibration unit can realize independent regulation and control, different working conditions can be achieved.

In the exhibition, NMS’s two giant machines attracted many professional participants to come for a visit and inquiry.

NMS booth

Ⅱ. The 5th Efficient & Advanced Crushing & Screening and Grinding Classification Technology Seminar

Dec. 4 to 6

Guangzhou City, China

Meanwhile, the 5th Efficient & Advanced Crushing & Screening and Grinding Classification Technology Seminar was held in Guangzhou City. The activity was jointly organized by the Institute of Resources Comprehensive Utilization of Guangdong Academy of Sciences, Faculty of Land Resources Engineering of Kunming University of Science and Technology, Xingfa School of Mining Engineering of Wuhan Institute of Technology, and College of Zijin Mining of Fuzhou University.

In the seminar, Sun Jidong, Deputy General Manager of Domestic Sales Company & General Manager of Mining Business Unit made a report entitled “development of efficient & advanced crushing & screening and comprehensive utilization of mineral resources”.

In the report, Sun Jidong introduced the general situation of the industry development, the concept of green development and the “green mine development plan for NMS”. According to his report, in recent years, while the country has increased investment in infrastructure construction, its requirements of environmental protection have been constantly improved, and accordingly, the investment in large-scale projects has increased, and the demand for large-scale equipment has also increased sharply. Before that, most of the cone crushers used in China were mainly smaller hydraulic cone crushers with spring structure, which was relatively low in automation, heavy and with low capacity, and they have little competitiveness compared with imported equipment. Therefore, domestic large-scale projects were almost monopolized by foreign brands.

CC800 single cylinder hydraulic cone crusher

In order to change this situation, after a long period of research and development, NMS adopted many advanced technologies and developed a super large-scale CC800 single cylinder hydraulic cone crusher in 2017. CC800 single cylinder hydraulic cone crusher is equipped with standard autorun automatic control system, which has the functions of constant outlet, liner life prediction, early warning and alarm, etc.; it’s equipped with 9 kinds of cavity types and 13 kinds of eccentricity to adapt to a variety of different working conditions; it adopts a new generation barotropic dust control system to improve the dust-proof effect; it uses the electronic relief valve instead of the accumulator and starts the overload protection through the sensor signal, which is faster and more accurate; it’s also equipped with two-way jack cylinder, the top shell of the upper rack can be removed automatically, and the maintenance of the equipment is simple and fast. The capacity of the equipment can reach more than 1800 tons, with the advantages of high production capacity, high degree of automation and low operation cost.

CC800 applied in Gucheng Project in Qingyuan, Guangzhou, China

At present, CC800 single cylinder hydraulic cone crusher has been applied in many projects. For example, four CC800-MF/ F were applied in Gucheng project in Qingyuan, Guangzhou. Compared with the original equipment replaced, the capacity is increased by 258.4t/h and the increase rate reached 35% under the condition of almost unchanged motor power.

NMS booth

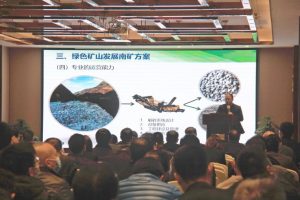

Ⅲ. 2020 China World-class Green and Intelligent Mine Construction Summit

Dec. 6 to 8

Jinan City, Shandong Province, China

From Dec. 6 to 8, 2020 China World-class Green and Intelligent Mine Construction Summit was held in Jinan City, Shandong Province. With the theme of “new era, new development – innovation promotes the upgrading of green intelligent mine construction”, the summit was jointly organized by Mine Processing Committee of China Mining Association, Mine Processing Academic Committee of Nonferrous Metals Society of China, Intelligent Mine Working Committee of China Mining Association, Environmental Protection Academic Committee of Nonferrous Metals Society of China, Mining Academic Committee of Nonferrous Metals Society of China, Shandong Gold Group Co., Ltd., and BGRIMM Technology Group Co., Ltd.

NMS booth

In the summit, Sun Jidong, Deputy General Manager of Domestic Sales Company & General Manager of Mining Business Unit made a report entitled “green and intelligent mine construction – development and application of crushing and screening technology and equipment”. In his report, he mentioned that in order to promote green intelligent mine construction, it is suggested that the comprehensive utilization should be integrated into the mine design for the newly-built mine, and the production line should be constructed by utilizing the resource advantages for tailings utilization, so as to realize the industrialization, intellectualization and large scale of mine construction. From the view of comprehensive optimization of process design, the large-scale equipment with the characteristics of large reduction ratio, high screening efficiency, large processing capacity and high intelligence meets the requirements of green mine construction better.

NMS has the leading equipment and products, professional operation ability and research and development ability. According to the market demand, the enterprise has launched a series of intelligent and large-scale equipment. GC series hydraulic gyratory crusher has the advantages of larger capacity, larger reduction ratio, better feeding size and gradation, automatic operation and monitoring, longer service life of liner and lower operation cost when compared with traditional gyratory crusher. JC series jaw crusher adopts the design of deep cavity symmetrical crushing chamber to maximize the feeding size, capacity and crushing wall, and the capacity can reach 1500t/h. MC series multi-cylinder hydraulic cone crusher, compared with the spring cone, has the advantages of larger moving cone diameter, lager eccentricity and larger size of the feeding port, and the product shape is better by using the lamination crushing principle.

In addition, NMS has also developed a SIP high-efficiency sand-making tower, which adopts dry sand-making with high capacity, high quality, low unit cost, environmental protection, stable performance and other characteristics. The sand-making tower runs stably in projects in Yunnan, Anhui and other places, and wins good reputation from customers.

Under the new development pattern, the development of green mines provides broader opportunities for domestic high-end equipment and service suppliers. NMS will seize the favorable development opportunities to meet the high requirements with superior quality and contribute to the development of green intelligent mines!

Ⅳ. 2020 (11th) China Mining Science & Technology Conference

Dec. 9 to 13

Maanshan City, Anhui Province, China

From Dec. 9 to 13, 2020 (11th) China Mining Science & Technology Conference was held in Maanshan City, Anhui Province. With the theme of the “achievements and prospects of mining science and technology during the 13th Five Year Plan period”, the conference was a communication activity in the industry, initiated by by Sinosteel Maanshan General Institute of Mining Research Co. Ltd., jointly organized by 23 colleges and universities, including Northeastern University, Central South University, University of Science and Technology Beijing, China University of Mining and Technology, etc., and more than 100 institutes including mining science and technology research institutes, key mining enterprises, key national research labs and engineering centers.

As one of the sponsors of the conference, NMS participated in the conference. During the conference, NMS had in-depth communication with colleagues in the industry.

NMS booth

Continuous exhibition and conference, unstoppable excellence. NMS is looking forward to having more opportunities to communicate with you and develop together!