Home >

Corporate News >

NMS Helps Huayou Cobalt (Zimbabwe Arcadia) Lithium Project to Trial Production Successfully

Home >

Corporate News >

NMS Helps Huayou Cobalt (Zimbabwe Arcadia) Lithium Project to Trial Production Successfully

2023.03.07

2023.03.07

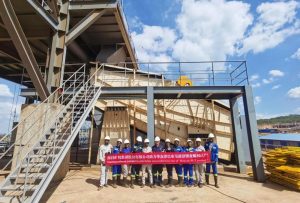

A few days ago, Huayou Cobalt lithium project in Arcadia, Zimbabwe has successfully entered the trial production stage. After the launch, it will greatly promote the development of mining industry in Zimbabwe and effectively alleviate the contradiction between supply and demand of lithium resources.

Arranging lithium supply chain, NMS equipment to serve the project

In the new era of energy transformation, carbon neutrality and carbon peak have moved from global consensus to action. Driven by the strong demand for new energy vehicles and energy storage, lithium ore, known as “white oil”, has become the most important strategic resource in the new energy era. Zimbabwe has the largest lithium deposit in Africa and it is the largest lithium producer in Africa, and its hard rock lithium reserves are the first in the world.

In 2021, Huayou Cobalt acquired 100% equity and related creditor’s rights of the prospect lithium in Zimbabwe for a consideration of $422 million, obtained 100% equity of the Arcadia lithium in Zimbabwe, and completed the delivery in April 2022. It is understood that Arcadia project, located on the outskirts of Harare, the capital of Zimbabwe, is considered to be one of the largest hard rock lithium resources in the world, with 1.9 million tons of lithium carbonate equivalent resources and 1.06% of lithium oxide grade, and has good prospects to get the ore. The project is close to the main highways and railway crossings, with convenient transportation.

The annual output of Arcadia Lithium Project is 950 tons, and EHS2060 grizzly screen, 2BS3673 banana screen, 2MLS4385-B banana screen and 2ZKR3675H linear screen produced by NMS are applied.

EHS2060 grizzly screen

2BS3673 banana screen

EHS2060 grizzly screen is used in the front of jaw crusher for primary crushing, which can effectively reduce the ore smaller than the jaw discharge opening entering the jaw, improve the crushing efficiency, and reduce the wear of the jaw liner and power consumption. 2BS3673 banana screen is for the fine crushing closed-circuit, which adopts the equal-thickness screening principle proposed by French Brest Rhine. The screen surface is arranged in five or six sections with different inclination angles. The unique structure makes it more suitable for the working conditions with a large number of fine particles in the material, and the classification effect of medium-fine ore is more significant. The finite element screen frame theory is used for infinite life design, and the large spacing design is convenient for maintenance. Self-synchronization technology is adopted, free of gear maintenance, low noise and high reliability.

2MLS4385-B banana screen

2ZKR3675H linear screen

2MLS4385-B banana screen is adopted for high-pressure roller closed-circuit inspection. This type of banana screen uses box-type vibrator as source, with the intensity up to 6G, so the excitation force is greater and stability is better. The vibrator is free of maintenance, and the service life is longer. Multi-angle screen surface arrangement is adopted, and the angle from feeding to discharging is reduced in order to achieve the effect of rapid material distribution and rapid screening. The screening area is up to 38.8 ㎡, which is 49.7% larger than model 3675 screening machine, and the processing capacity is greatly increased. 2ZKR3675H linear screen is used for grading operation in the grinding workshop.

Cooperations achieved to make customer easy

During the construction of Huayou Cobalt Lithium Project in Arcadia, Zimbabwe, NMS after-sales service engineer was stationed at the site to provide technical guidance for the whole process of equipment installation, commissioning, trial production, etc., and technical training for the demander’s personnel, providing a solid technical guarantee for the smooth implementation of the project.

This is not the first cooperation between NMS and Huayou Cobalt Industry. Zhejiang Huayou Import and Export Co., Ltd., a subsidiary of Huayou Cobalt Industry, has purchased MC400 multi-cylinder hydraulic cone crusher from NMS, and several MC500 multi-cylinder hydraulic cone crushers and BS3073 banana screens have been used in Indonesia Huafei Nickel Cobalt Hydrometallurgy Project. Based on the good application of NMS crushing and screening equipment in the project, users give priority to NMS when selecting and purchasing equipment for the Zimbabwean lithium project.

In 2017, NMS set up a branch in Africa with service points covering southern, central and western Africa, and built a storage base in Johannesburg, South Africa, radiating central and southern Africa. The perfect service system, timely and effective technical support, and adequate spare parts guarantee are also the reasons why users firmly choose to cooperate with NMS.

In addition, in the early stage of equipment selection, NMS also uses the self-developed YCJ and YMS to analyze the rock processing characteristics of the project, help equipment selection, and uses the new process calculation software FlowSheet Designer independently developed by NMS Swedish Research and Development Center to calculate the flow and product ratio, and help optimize the process flow, reduce costs and increase efficiency for customers.

In recent years, NMS has actively responded to the initiative of jointly building the “the Belt and Road”, actively carried out business layout along the “the Belt and Road”, and followed the pace of Chinese enterprises by providing localized services to expand overseas business opportunities. 2023 is the 10th anniversary of the “the Belt and Road” initiative, which will surely bring new opportunities for Chinese enterprises to “go global”. NMS will make full use of domestic and foreign resources, seize the opportunity with a more active posture, do a good job of localization while improving itself, increase the overseas sales and service network layout, enhance the recognition of international market, and strive to build NMS into an international well-known brand in the future.